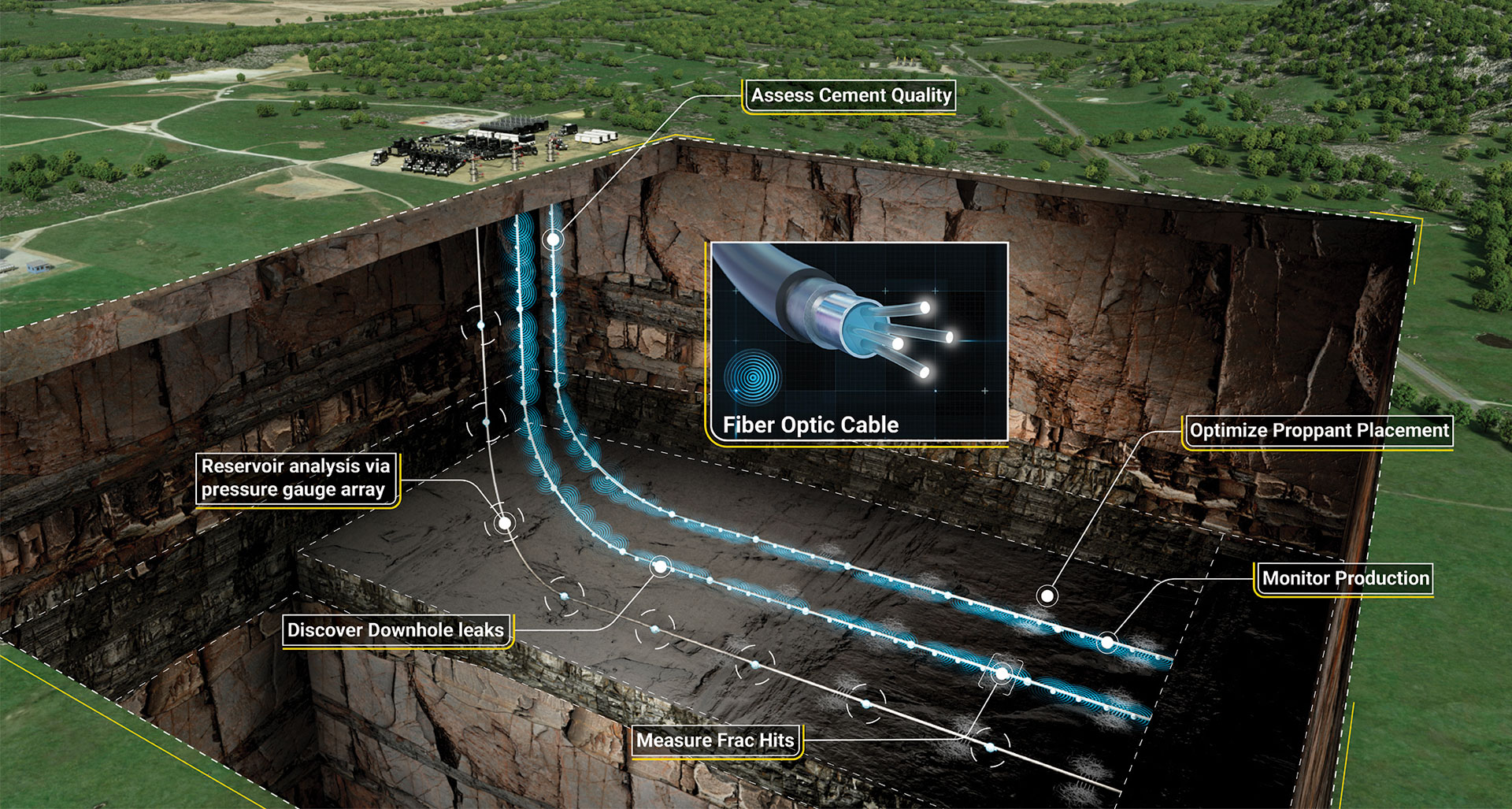

Downhole Fiber Optic sensing technology allows for data collection across an entire wellbore, for the life of the well, in a reliable and cost-effective manner. Since 2008, SageRider has become a leader in this field of optical sensing systems. Due to SageRider’s broad knowledge base in both fiber optic sensing technology and oilfield services, we are well suited for the engineering and operational demands of the industry. We offer comprehensive monitoring solutions, including design, installation, analysis/reporting and support for the life of the system.

Monitoring systems include custom fiber optic cables suitable for any downhole environment; along with cable protection and a variety of temporary and permanent surface data acquisition systems that allow for real-time data delivery directly to the client's office. When using permanent fiber optic distributed sensing systems, operators can capture critical thermal and acoustic events to help eliminate the risk of well intervention. SageRider’s excellent track record in casing conveyed sensor deployment has proven to be invaluable to the successful installation of these systems.

See this technology and more on our YouTube page here: youtube.com/@sageriderinc

Deployable on tubing, casing or coiled tubing

Suitable for temperatures up to 300° C

Distributed temperature, acoustics and strain on the same cable

Allows for data collection without well intervention or changes in well operation

Real time data collection during cementing, frac, flowback and production

Distributed temperature sensing

Distributed acoustic sensing

Distributed strain sensing

Distributed pressure sensing - in development

Continuous production logging

Frac & stimulation monitoring

Injection profiling

Artificial lift monitoring

Leak detection

Completion integrity monitoring

SAGD sub cool optimization

CSS & thermal recovery optimization

Project engineering and management

Project feasibility studies and system design

Intergrated installation services

Data analysis and reporting

Data management

Field to desk data telemetry and storage

Data visualization