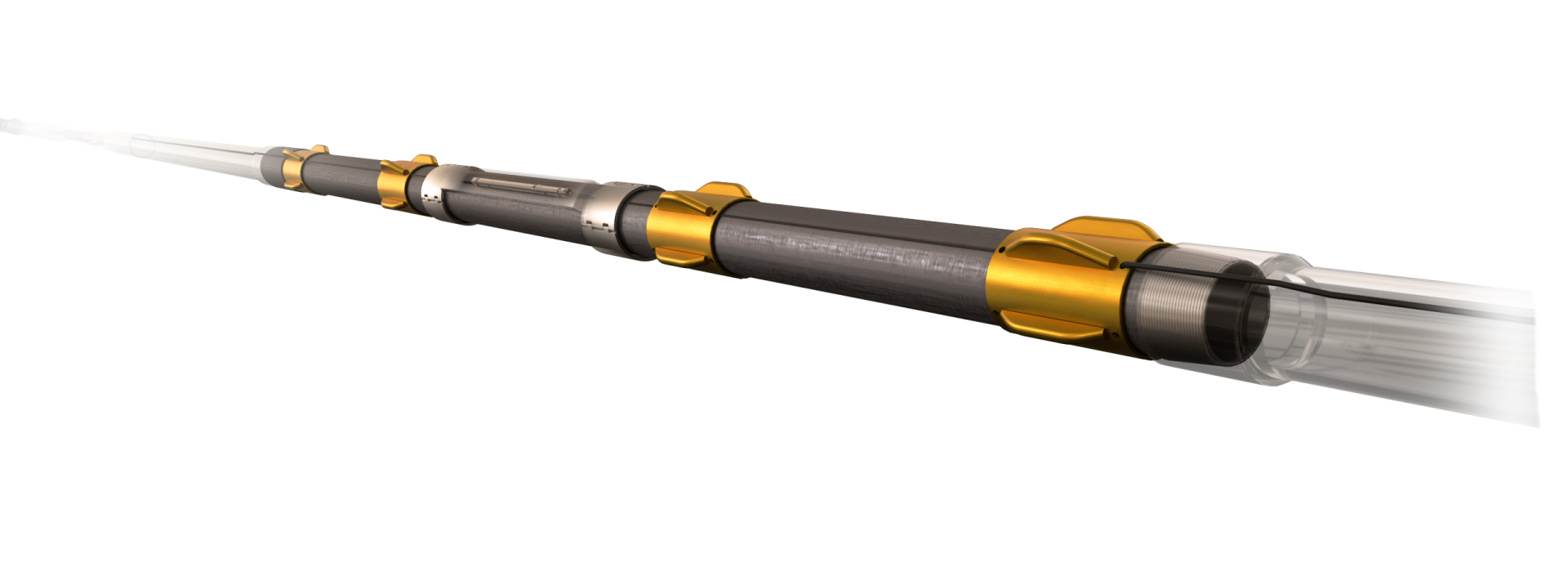

Introducing our innovative Casing Conveyed Gauge Monitoring System. The SageWatch Subsurface Surveillance System provides real-time pressure and temperature data for many applications. Its unique design allows for simultaneous monitoring of unlimited points within a single wellbore with any casing size.

The SageWatch™ Subsurface Surveillance System is a proven method for gathering long and short term data for a wide base of applications. Through a better understanding of reservoir parameters, connectivity, field drainage, and stimulation processes, SageWatch™ creates high-level value through a better understanding of reservoir parameters.

See this technology and more on our YouTube page here: youtube.com/@sageriderinc

Ability to monitor reservoir activity only, internal casing activity only, or a combination of the two. It is cemented into place to provide isolation between zones.

Applications have progressed beyond monitor-only wells. The system can also be installed for completion wells and those monitored with the real-time downhole P/T gauges in place. Multiple monitoring points can also be ported to read internal pressures at any point along the wellbore.

It is installed permanently behind pipe and conveyed as an integral part of the casing string. All communication and power lines run along the outside of the casing to the surface. Once cemented into place, the P/T gauges are connected to the reservoir through perforations allowing for continuous real-time, undisturbed data.

Reservoir definition, establishing true perm, identifying crossflow

Well spacing optimization

Verifying injection pressures, migration

Identification of unusual geology

Modeling verification and calibration

Offset fracturing

Downhole fracture monitoring

Ability to run in conjunction with fiber optics

It can monitor individual sections within the wellbore. Isolation is achieved through hydraulic or swellable packers.

Even during drilling, stimulation, and production, data will be collected. Each individual monitoring point along the wellbore is isolated giving true individual points of data. Powered from the surface, this method collects data which can be accessed locally or transmitted wirelessly via any typical field SCADA system.

Can be run in small or large casing

Can take advantage of old vertical wells

Can be installed above areas of collapsed casing

Provides data to monitor close proximity new wells